Time:2025-08-22 19:03:32 Browse:50

Modern society cannot do without electronic products, and the most basic component of electronic products is the circuit board. Circuit boards are carriers of electronic components, widely used in various fields such as communication, computers, industrial automation, automotive electronics, medical devices, etc. For electronic product manufacturing, circuit board surface mount processing is an essential step. Through this step, electronic products can be made more refined and practical. This article will provide a detailed introduction to the process of circuit board surface mount manufacturing.

What is circuit board surface mount processing?

SMT processing of circuit boards refers to a process of soldering electronic components onto the surface of a circuit board. SMT refers to a form of electronic component during soldering. In surface mount devices, the pins of the components are set at the bottom and soldered to the surface of the circuit board. SMT processing of circuit boards is a more commonly used manufacturing method compared to plug-in processing in the process of circuit board production.

The Importance and Advantages of SMT Processing for Circuit Boards

Compared to plug-in processing, circuit board surface mount processing has the following advantages:

Ensure process accuracy: Surface mount devices are highly precise electronic components that are designed for modern packaging technology. Their characteristic is that the pins have already been molded out of the shape of the surface mount component, and the resulting size is small and lightweight, which reduces the limitations on the board layout and ensures the overall performance of the product.

Helps improve production efficiency: In circuit board surface mount processing, components can be automatically positioned, loaded, calibrated, photographed, and other operations, saving a lot of manual operation time and labor costs.

Low maintenance and repair costs: Due to direct soldering on the surface of the circuit board, in most cases, it can reduce damage and looseness caused by repeated pin insertion and removal, resulting in relatively low maintenance costs.

Small size and light weight: Due to the small size of the components, there is no need for wire connections, resulting in a high density of layout. The overall size of the motor product is small and light weight.

Detailed explanation of the production process of circuit board surface mount processing

Step 1: Selection of SMT materials

Before starting the SMT processing of circuit boards, it is necessary to choose high-quality SMT materials, which is beneficial for improving product quality and reducing the probability of damage caused by poor SMT materials. There are many different types of patch materials on the market now, and manufacturers usually choose the appropriate material according to their own needs.

Step 2: Confirmation of Component Specifications and Models

After purchasing suitable patch materials, it is necessary to determine the specifications and models of the components to be used. Different models and specifications have different working modes and characteristics, and need to be selected according to actual needs. At the same time, these planned component specifications and models should be recorded in the BOM.

Step 3: SMT Surface Mount

SMT is a surface mount technology that directly solder components onto the surface of a PCB board. Compared to plug-in processing, SMT has higher efficiency. The specific operation process of SMT includes printing, surface mounting, reflow soldering, and other operations.

Step 4: Board making

Firstly, it is necessary to create a blueprint for the PCB circuit board, select suitable boards, and cut and mill holes. Then, the surface mounted components are fed into the finished product store through a feeder and sent for reflow soldering and other post production work.

Step 5: Test Quality

This step is used to test the effectiveness of the patch. Evaluate the finished product through testing and other means to ensure the integrity of the entire manufacturing process

The above is the production process of circuit board surface mount processing.

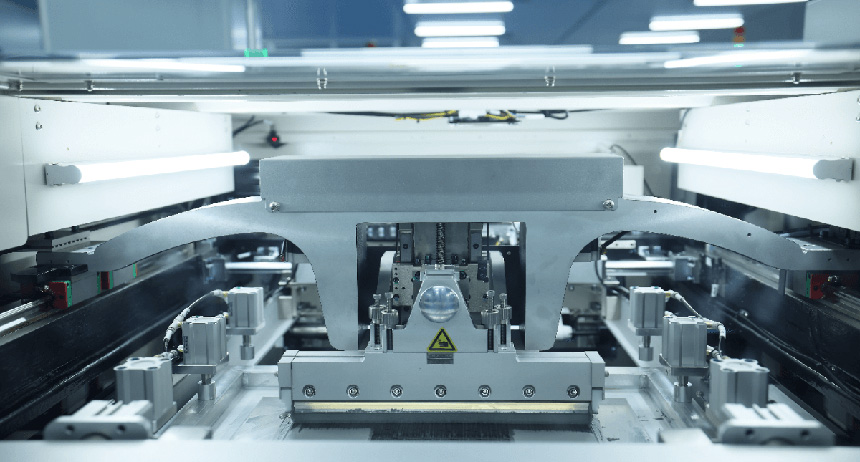

Selection of factories and equipment

The SMT processing of circuit boards requires some professional equipment to assist in production, and the selection of good equipment and factories is of great importance that cannot be ignored. Firstly, we need to put in a lot of effort on the equipment, choosing professional equipment from various surface mount processing equipment to truly implement it. At the same time, we need to choose experienced factories to ensure product quality and production efficiency improvement.

Common SMT processing techniques for circuit boards

1. Surface Mount Technology (SMT)

SMT is a popular PCB surface mount technology and has always been the most commonly used surface mount electronic device technology in the electronics manufacturing industry, as it can save time and costs and does not require complex processing and assembly of circuit boards.

2. Time Transfer Technique (LDT)

LDT is a chemical etching method for circuit boards, which is very efficient, simple, and inexpensive. However, due to the poor quality of the etching solution, it may cause serious pollution to the environment, and the construction of complex circuit boards will be more difficult to achieve. Therefore, this technology is less commonly used.

Preparation work before SMT processing of circuit boards

Before performing circuit board surface mount processing, some preparatory work needs to be done, including checking the quality of components, inspecting the board, confirming technical parameters, and recording BOM, etc. Executing these preliminary tasks can provide assurance for the entire production process.

Precautions and Frequently Asked Questions

During the process of circuit board surface mount processing, the following points should be noted:

1. The precision of component selection should not be lower than that of the machining process.

2. The working environment needs to avoid interference from its magnetic and electric fields as much as possible.

3. Check if the components have achieved sufficient conductivity.

4. The temperature is an important factor affecting the performance of the circuit board.