Time:2025-08-24 19:02:36 Browse:40

In today's digital age, the popularity of electronic products is increasing, and PCBA board, as one of the core components of electronic products, plays a very important role. It is not only a carrier that connects various chips inside the device, but also enables various control and processing of the device, but its manufacturing process is very complex.

Basic principles of SMT surface mount technology

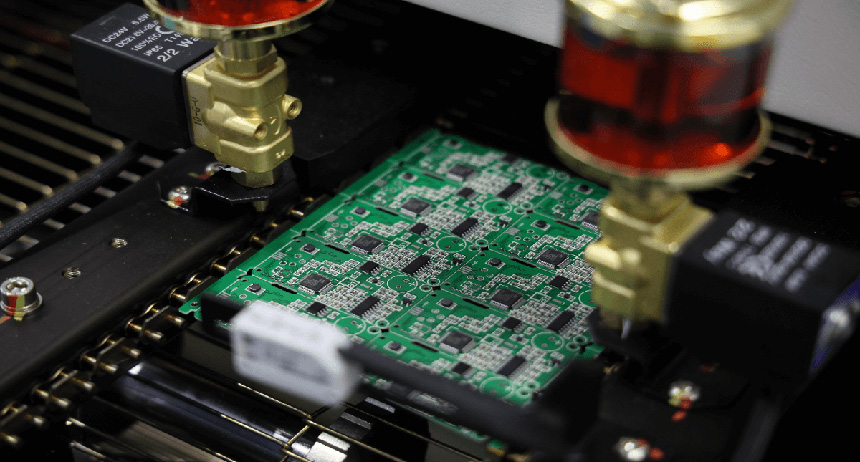

The manufacturing process of PCBA board adopts SMT surface mount technology. The basic principle is to paste the surface of electronic components onto the PCB board and achieve perfect connection with the PCB board through high-temperature soldering technology. The process of SMT surface mount technology includes steps such as screen printing, component mounting, reflow soldering, and testing. Screen printing is the process of applying solder paste onto a PCB board in preparation for attaching electronic components; Component mounting is the process of attaching components onto a PCB board using solder paste; Reflow soldering is the process of placing a PCB board in a high-temperature furnace, allowing solder paste to heat up and coat the solder joints. After the temperature drops, the solder paste solidifies into solder joints; Testing is to check whether the quality of the solder joints meets the standards and ensure the quality of the surface mount.

The background and significance of the PCBA board SMT production process lies in its ability to efficiently integrate electronic components onto the PCB board, improving the quality and performance of electronic products. This can not only reduce production costs and improve production efficiency, but also enhance the reliability and stability of products, making electronic products have a longer service life and better user experience. Therefore, in today's digital age, the research and improvement of PCBA board surface mount production technology is of great significance.

SMT assembly process is a modern electronic manufacturing process that integrates microelectronic devices onto a chip and assembles them onto a printed circuit board to achieve high-speed, high reliability, and high-performance electronic devices.

Here are some basic steps of SMT assembly process:

1. Parts preparation: Before the SMT assembly process begins, various parts need to be prepared, such as electronic components, wires, connectors, solder, ceramic materials, etc. These parts need to be tested and screened to ensure their quality and reliability.

2. Plugin: Insert electronic components into slots on a printed circuit board. This process requires the use of professional equipment and tools to ensure the accuracy and consistency of the plugins.

3. Welding: Heat the solder through a heat source and adhere it to printed circuit boards and electronic components. This process requires the use of professional tools and techniques to ensure the quality and reliability of welding.

4. Testing: After the SMT assembly process is completed, electronic devices need to be tested to ensure that their functionality and performance meet the requirements. This process requires the use of professional testing equipment and tools to ensure the accuracy and reliability of the testing.

5. Mounting: Mounting solder pads or other components onto a printed circuit board. This process requires the use of professional equipment and tools to ensure the accuracy and consistency of the installation.

6. Rework: If there are problems during SMT assembly, such as misalignment of plugins, poor soldering, etc., they need to be reworked. This process requires the use of professional tools and techniques to ensure the quality and reliability of rework.

7. Packaging: Finally, package the electronic devices for transportation and storage. This process requires the use of professional packaging equipment and materials to ensure the integrity and stability of the packaging.

In short, SMT assembly process is a highly automated electronic manufacturing process that can greatly improve the manufacturing efficiency and quality of electronic devices. By using the correct steps and tools, errors and defects can be effectively reduced, thereby achieving high-quality, high reliability, and high-performance electronic devices.

Environmental and safety aspects of PCBA board SMT production

The production process of SMT requires a large amount of chemical reagents and hazardous materials, so environmental protection and safety are also issues that need to be highly valued. Therefore, strict safety monitoring measures need to be taken during the production process to ensure the physical health of workers and the safety of the environment.

Market Development and Future Prospects of PCBA Board SMT Production

PCBA board mounting is a very important part of the current electronics industry, and its production technology is constantly developing and improving. With the emergence of new technologies such as 5G and artificial intelligence, PCBA board mounting will also usher in a broader market prospect. This will promote more production enterprises to improve their technology and process level, ensuring that PCBA board placement plays a more important role in future development.

In this article, we introduced the basic introduction of PCBA board surface mount production, including SMT surface mount process, device mounting, production line, and testing and acceptance. This knowledge needs to be learned and mastered in combination with professional technical knowledge and practical experience, only in this way can the quality and efficiency of SMT production be improved.